24

2025

-

07

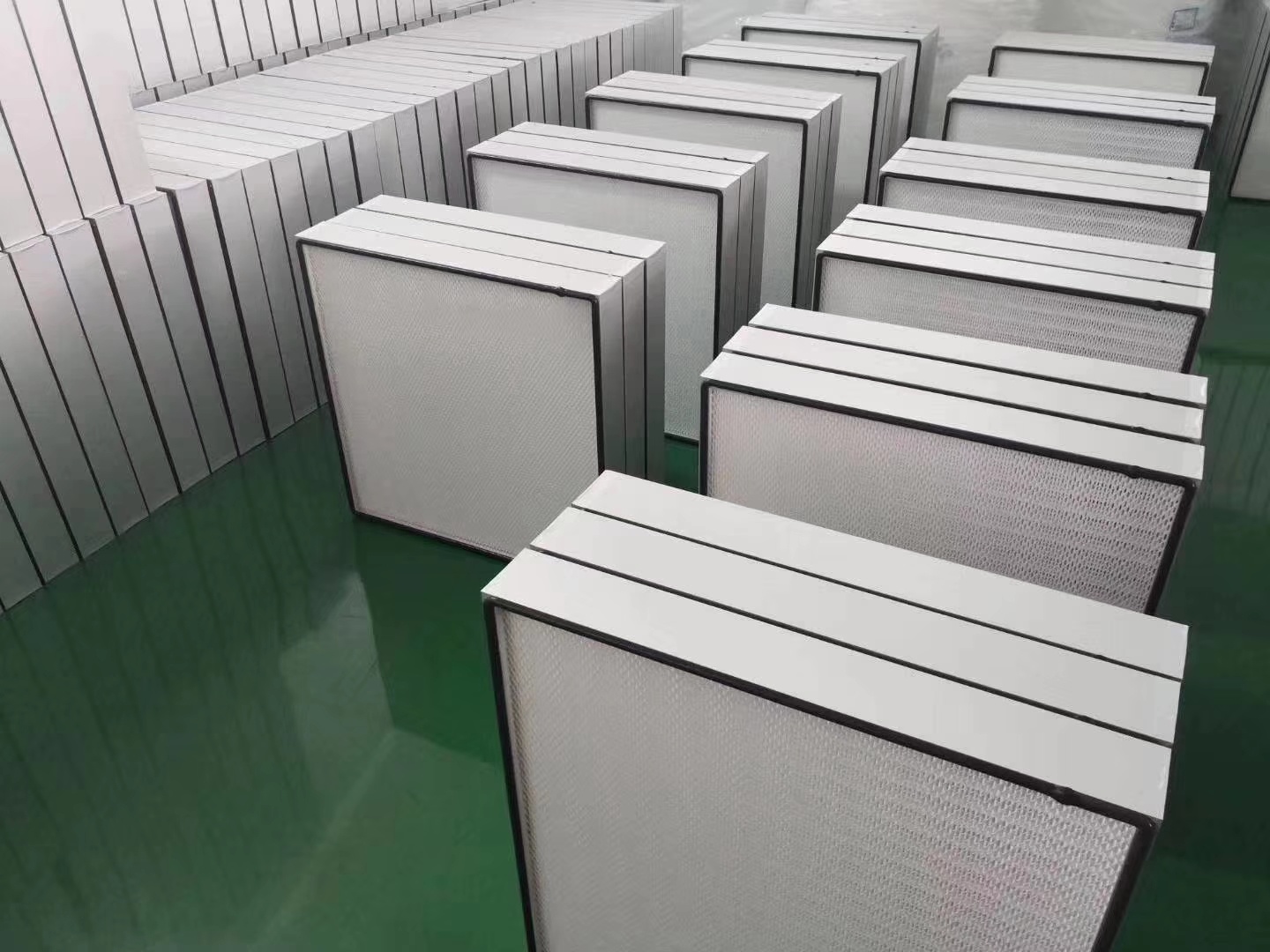

Advanced HEPA Filter Media Solutions for Superior Air Purification

Discover high-efficiency HEPA filter media designed to capture 99.97% of particles at 0.3 microns, ensuring clean and healthy air in diverse applications.

Author:

HEPA Filter Media The Cornerstone of Advanced Air Filtration Technology

High-Efficiency Particulate Air (HEPA) filter media has become a fundamental element in air purification technology, ensuring the removal of microscopic airborne contaminants with outstanding efficiency. Designed to trap at least 99.97% of particles as small as 0.3 microns, HEPA filter media is essential in maintaining clean air in various critical environments ranging from medical facilities to industrial clean rooms and residential air purifiers.

Understanding HEPA Filter Media

HEPA filter media consists of a dense network of randomly oriented fibers, usually made of ultra-fine fiberglass. These fibers create a tortuous path through which air must pass, forcing particles to adhere through multiple mechanisms such as interception, inertial impaction, and diffusion. Unlike conventional filters that primarily trap larger particles, HEPA media is engineered to capture extremely fine particulate matter including dust, pollen, pet dander, mold spores, bacteria, and certain airborne viruses.

The high filtration efficiency of HEPA media is measured based on its ability to remove particles at the most penetrating particle size (MPPS), which is approximately 0.3 microns. This size is considered the most difficult to capture, and HEPA filters must meet stringent standards, typically set by regulatory bodies like the U.S. Department of Energy (DOE), to qualify as true HEPA.

Key Parameters of HEPA Filter Media

The performance and suitability of HEPA filter media depend on several technical parameters:

Particle Removal Efficiency: The minimum 99.97% efficiency at 0.3 microns is a defining feature, but many HEPA medias achieve even higher efficiency rates.

Airflow Resistance (Pressure Drop): This parameter determines how much energy is needed to push air through the filter. A balance must be maintained between filtration efficiency and airflow to optimize energy consumption.

Thickness and Weight: These affect both the filtration capacity and the structural integrity of the media.

Durability and Moisture Resistance: In many applications, HEPA media is exposed to humidity and varying conditions, so it must maintain its performance over time.

Chemical and Temperature Resistance: For industrial or specialized environments, the filter media must resist chemical degradation and withstand temperature variations.

Typical specifications of such HEPA filter media include:

Material Composition: High-quality fiberglass ensuring excellent particle capture and durability.

Efficiency Rating: Meets or exceeds HEPA standards with 99.97% efficiency at 0.3 microns, suitable for high cleanliness requirements.

Thickness: Approximately 1.5 mm, balancing filtration depth and airflow.

Basis Weight: Around 130 g/m², providing strength while maintaining flexibility.

Airflow Resistance: About 150 Pa pressure drop at rated airflow, improving system energy efficiency.

Operating Temperature Range: From -40°C to 90°C, fitting various industrial and commercial needs.

Moisture Resistance: Fiberglass construction inherently resists moisture, minimizing degradation risk.

Dimensions: Typically supplied in rolls with a width of 1000 mm and variable length, facilitating large-scale production and replacement.

These parameters illustrate a balanced design, ensuring stable and efficient filtration across multiple applications.

Applications of HEPA Filter Media

The excellent particle capture capacity of HEPA filter media makes it widely applicable in various industries and consumer products:

Medical and Healthcare Facilities: HEPA media ensures sterile, contaminant-free air in operating rooms, isolation wards, and laboratories, protecting patients and experimental accuracy.

Clean Rooms and Semiconductor Manufacturing: Critical manufacturing processes require ultra-clean environments, and HEPA filter media helps meet stringent cleanroom standards.

Residential Air Purifiers: Removes allergens, dust, and airborne pathogens to improve indoor air quality and respiratory health.

HVAC Systems: Commercial buildings and public spaces use HEPA media to enhance air quality and occupant health.

Industrial Filtration: Factories handling powders, chemicals, or sensitive components use HEPA filters to protect workers and processes.

Advantages of Using Advanced HEPA Filter Media

Combining high filtration efficiency with physical durability, HEPA filter media is the preferred choice for critical filtration needs:

High Particle Capture Efficiency: Capable of filtering ultra-fine pathogens and particles.

Improved Air Quality: Significantly reduces airborne contaminants, promoting health and comfort.

Energy Efficiency: Optimized fiber structure lowers pressure drop and energy consumption.

Long Service Life: Durable construction withstands environmental challenges for consistent performance.

Versatility: Suitable for residential, commercial, and industrial applications.

Maintenance and Replacement Recommendations

Although HEPA filter media offers superior filtration, proper maintenance is essential. Over time, accumulated particles increase pressure drop, requiring periodic replacement or cleaning. Choosing high-quality media extends filter life and reduces maintenance frequency.

Conclusion

HEPA filter media is a key technology for achieving clean air, providing filtration efficiencies above 99.97%, far exceeding conventional filters. By employing premium fiberglass, optimal thickness, and excellent moisture resistance, HEPA media delivers stable, efficient, and energy-saving air purification solutions across various environments.

Whether for industrial or residential use, selecting advanced HEPA filter media means prioritizing health, safety, and environmental quality. As global air quality concerns grow, HEPA filter media’s role in safeguarding human health and maintaining clean indoor air continues to increase in importance.

Related news

2024-04-16

2022-01-10