High-efficiency activated carbon purification cabinet, UV photolysis purification cabinet

Subcategory:

Model:

Brand:

Waste gas purification equipment (high-efficiency activated carbon purification cabinet, UV photolysis purification cabinet)

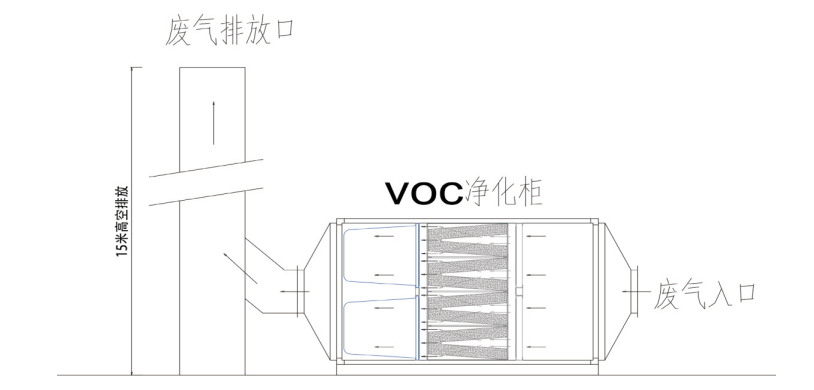

Uses and Usage: Purification of various commercial and industrial waste gas emissions, used in conjunction with exhaust emission systems.

- Purification of various commercial waste gas emissions

- Purification of various industrial waste gas emissions

- Purification of various odor gas emissions

- Purification of various malodorous gas emissions

- Purification of various harmful and toxic gas emissions

Materials and Characteristics:

Purification materials: Primary filtration layer, activated carbon adsorption layer, photocatalytic purification

Cabinet material: Galvanized steel plate / Stainless steel

Features:

1. Highly efficient purification of organic waste gas, can effectively remove volatile organic compounds (VOCs), inorganic substances, hydrogen sulfide, ammonia, mercaptans, styrene, butyl acrylate, etc.

2. No need to add any chemical substances, only need to set up corresponding exhaust pipes and exhaust power, so that organic gases are decomposed and purified through this equipment, without the need to add any chemical substances to participate in the chemical reaction.

3. Wide range of applications, adaptable to high and low concentrations, large air volumes, and purification of different organic gas substances, can work continuously 24 hours a day, stable and reliable operation.

4. Low operating cost, this equipment has no mechanical action, no noise, no need for dedicated personnel management and daily maintenance, only regular inspections are required, the equipment has low energy consumption, and the equipment wind resistance is extremely low <50pa, which can save a lot of exhaust power energy consumption; and according to the customer's actual production conditions and waste gas concentration, set up a multi-stage operation mode to effectively reduce operating costs.

5. Small equipment footprint, light weight: Suitable for compact layouts and confined spaces.

6. Optional high-quality imported stainless steel material: waterproof, fireproof, explosion-proof, corrosion-resistant, long service life.

7. High technological content, using advanced advanced oxidation technology, breaking through the limitations of a single system reaction, in the entire reaction system, there are two oxidizing agents with extremely strong oxidation ability - O3 and ·OH participate in the reaction, making the deodorization effect better.

8. Higher degree of mineralization of organic gases, harmless discharge, no secondary pollution.

Technical Specifications

|

||||||

Model |

External Dimensions |

Inlet and Outlet Size |

Air Handling Capacity |

Activated Carbon Cross-sectional Area |

Design Air Velocity |

Equipment Resistance |

(mm) |

(mm) |

(m³/h)

|

(㎡)

|

(m/s)

|

(Pa)

|

|

FRS-EGPE-YJH-06

|

L 1490*W1880*H2500

|

350*350

|

6000

|

2.16

|

400

|

|

FRS-EGPE-YJH-09

|

L 2210*W1880*H2500

|

500*500

|

9000

|

3.24

|

≤0.8 |

400

|

FRS-EGPE-YJH-12

|

L 2930*W1880*H2500

|

600*600

|

12000

|

4.32

|

≤0.8 |

400

|

FRS-EGPE-YJH-15

|

L 3650*W1880*H2500

|

650*650

|

15000

|

5.4

|

≤0.8 |

400

|

FRS-EGPE-YJH-20

|

L 3650*W2490*H2500

|

700*700

|

20000

|

7.2

|

≤0.8 |

400

|

FRS-EGPE-YJH-25

|

L 4370*W2490*H2500

|

750*750

|

25000

|

8.64

|

≤0.8 |

400

|

FRS-EGPE-YJH-30

|

L 5090*W2795*H2500

|

800*800

|

30000

|

10

|

≤0.8 |

400

|

PRODUCTS

CONTACT

D4 Fenggong Area Nansha Village Danzao Town Nanhai District , Foshan City, Guangdong PR. China.

Waste gas purification equipment (high-efficiency activated carbon purification cabinet, UV photolysis purification cabinet)

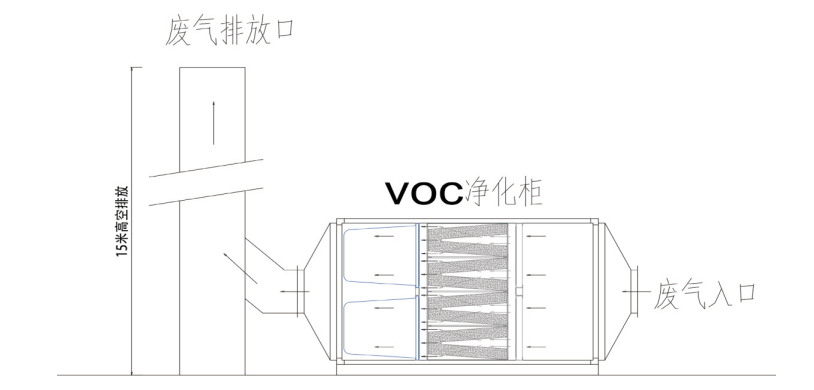

Uses and Usage: Purification of various commercial and industrial waste gas emissions, used in conjunction with exhaust emission systems.

- Purification of various commercial waste gas emissions

- Purification of various industrial waste gas emissions

- Purification of various odor gas emissions

- Purification of various malodorous gas emissions

- Purification of various harmful and toxic gas emissions

Materials and Characteristics:

Purification materials: Primary filtration layer, activated carbon adsorption layer, photocatalytic purification

Cabinet material: Galvanized steel plate / Stainless steel

Features:

1. Highly efficient purification of organic waste gas, can effectively remove volatile organic compounds (VOCs), inorganic substances, hydrogen sulfide, ammonia, mercaptans, styrene, butyl acrylate, etc.

2. No need to add any chemical substances, only need to set up corresponding exhaust pipes and exhaust power, so that organic gases are decomposed and purified through this equipment, without the need to add any chemical substances to participate in the chemical reaction.

3. Wide range of applications, adaptable to high and low concentrations, large air volumes, and purification of different organic gas substances, can work continuously 24 hours a day, stable and reliable operation.

4. Low operating cost, this equipment has no mechanical action, no noise, no need for dedicated personnel management and daily maintenance, only regular inspections are required, the equipment has low energy consumption, and the equipment wind resistance is extremely low <50pa, which can save a lot of exhaust power energy consumption; and according to the customer's actual production conditions and waste gas concentration, set up a multi-stage operation mode to effectively reduce operating costs.

5. Small equipment footprint, light weight: Suitable for compact layouts and confined spaces.

6. Optional high-quality imported stainless steel material: waterproof, fireproof, explosion-proof, corrosion-resistant, long service life.

7. High technological content, using advanced advanced oxidation technology, breaking through the limitations of a single system reaction, in the entire reaction system, there are two oxidizing agents with extremely strong oxidation ability - O3 and ·OH participate in the reaction, making the deodorization effect better.

8. Higher degree of mineralization of organic gases, harmless discharge, no secondary pollution.

Technical Specifications

|

||||||

Model |

External Dimensions |

Inlet and Outlet Size |

Air Handling Capacity |

Activated Carbon Cross-sectional Area |

Design Air Velocity |

Equipment Resistance |

(mm) |

(mm) |

(m³/h)

|

(㎡)

|

(m/s)

|

(Pa)

|

|

FRS-EGPE-YJH-06

|

L 1490*W1880*H2500

|

350*350

|

6000

|

2.16

|

400

|

|

FRS-EGPE-YJH-09

|

L 2210*W1880*H2500

|

500*500

|

9000

|

3.24

|

≤0.8 |

400

|

FRS-EGPE-YJH-12

|

L 2930*W1880*H2500

|

600*600

|

12000

|

4.32

|

≤0.8 |

400

|

FRS-EGPE-YJH-15

|

L 3650*W1880*H2500

|

650*650

|

15000

|

5.4

|

≤0.8 |

400

|

FRS-EGPE-YJH-20

|

L 3650*W2490*H2500

|

700*700

|

20000

|

7.2

|

≤0.8 |

400

|

FRS-EGPE-YJH-25

|

L 4370*W2490*H2500

|

750*750

|

25000

|

8.64

|

≤0.8 |

400

|

FRS-EGPE-YJH-30

|

L 5090*W2795*H2500

|

800*800

|

30000

|

10

|

≤0.8 |

400

|

Leave A Message

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.