15

2025

-

09

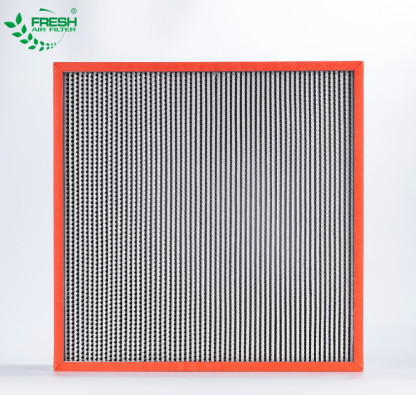

High-Temperature Deep-Pleat HEPA Filters: Advanced Air Purification for Extreme Conditions

Author:

In modern industrial, laboratory, and cleanroom environments, air quality, safety, and reliability are paramount. The High-Temperature Deep-Pleat HEPA Filter is engineered to meet these rigorous demands, providing high-efficiency filtration even under extreme thermal conditions. Designed with advanced media and robust construction, this filter ensures consistent performance, long service life, and superior protection for sensitive equipment, products, and personnel.

Main Framework & Structure

High-Temperature Deep-Pleat HEPA Filters feature densely packed pleated filtration media made from heat-resistant fibers. The deep-pleat design maximizes surface area, enhancing dust-holding capacity and extending service life. Frames are constructed from high-grade steel or aluminum, ensuring structural integrity under high-temperature operation. The filter is designed to withstand continuous airflow in demanding applications, maintaining efficiency without deformation or collapse. Optional gasketing and sealing systems provide airtight installation, preventing bypass and ensuring maximum filtration efficiency.

This filter can be customized according to customer requirements to withstand continuous operating temperatures of 250–300°C, with an instantaneous resistance of up to 320°C. The filtration media consists of high-temperature resistant fiberglass filter paper and aluminum foil corrugated separators, while the sealant glue is designed to endure continuous high temperatures up to 300°C, withstanding peaks of 320°C.

Product Advantages

- High Filtration Efficiency – Removes 99.97% of particles ≥0.3 microns, safeguarding cleanroom and industrial environments.

- Heat-Resistant Design – Operates reliably in high-temperature environments without media degradation or warping.

- Deep-Pleat Structure – Maximizes surface area, improving dust-holding capacity and reducing maintenance frequency.Durable Construction – Robust frames and reinforced media withstand extreme conditions and high airflow.

- Versatile Applications – Suitable for industrial furnaces, high-temp cleanrooms, pharmaceutical processing, and HVAC systems in harsh environments.

Applications and Functions

These filters are essential in industries where both high air purity and elevated temperature tolerance are required. Common applications include chemical processing plants, pharmaceutical cleanrooms, semiconductor manufacturing, high-temperature industrial ovens, and HVAC systems in laboratories. They protect sensitive equipment from particulate contamination, improve product quality, and ensure a safe working environment. Their performance is critical in processes where airborne particles can compromise safety, production integrity, or regulatory compliance.

Customer Pain Points & Solutions

Organizations often face challenges such as:

- Reduced filter life and efficiency due to high-temperature air streams.

- Risk of contamination in sensitive manufacturing or laboratory environments.

- Frequent maintenance and downtime due to filter degradation.

High-Temperature Deep-Pleat HEPA Filters address these issues by:

- Utilizing heat-resistant filtration media to maintain efficiency under extreme temperatures.

- Incorporating deep-pleat designs for higher dust-holding capacity, reducing service intervals.

- Employing robust frames and sealing to prevent bypass and maintain cleanroom standards.

- Supporting critical applications that require reliable air filtration without interruption.

Case Study & Success Story

A semiconductor manufacturing facility faced frequent filter replacements due to high-temperature exhaust air, causing production interruptions and increased costs. After switching to High-Temperature Deep-Pleat HEPA Filters, the facility experienced 50% longer filter life, improved particulate control, and reduced downtime. Cleanroom compliance was maintained effortlessly, and equipment protection significantly improved. Maintenance teams appreciated the reduced handling frequency, and production staff noted a consistent quality environment for sensitive wafers, reinforcing the value of investing in high-performance, heat-resistant HEPA filtration.

Conclusion

The High-Temperature Deep-Pleat HEPA Filter is a critical component for industries requiring superior air purification under challenging thermal conditions. By combining exceptional filtration efficiency, heat resistance, and durability, these filters safeguard equipment, improve product quality, and maintain regulatory compliance. Ideal for cleanrooms, industrial processes, and HVAC systems exposed to elevated temperatures, they reduce maintenance, minimize downtime, and ensure a safe, controlled environment. Investing in high-temperature deep-pleat HEPA filters offers reliable, long-term protection, helping organizations meet both operational and quality standards with confidence.

Related news

2024-04-16

2022-01-10